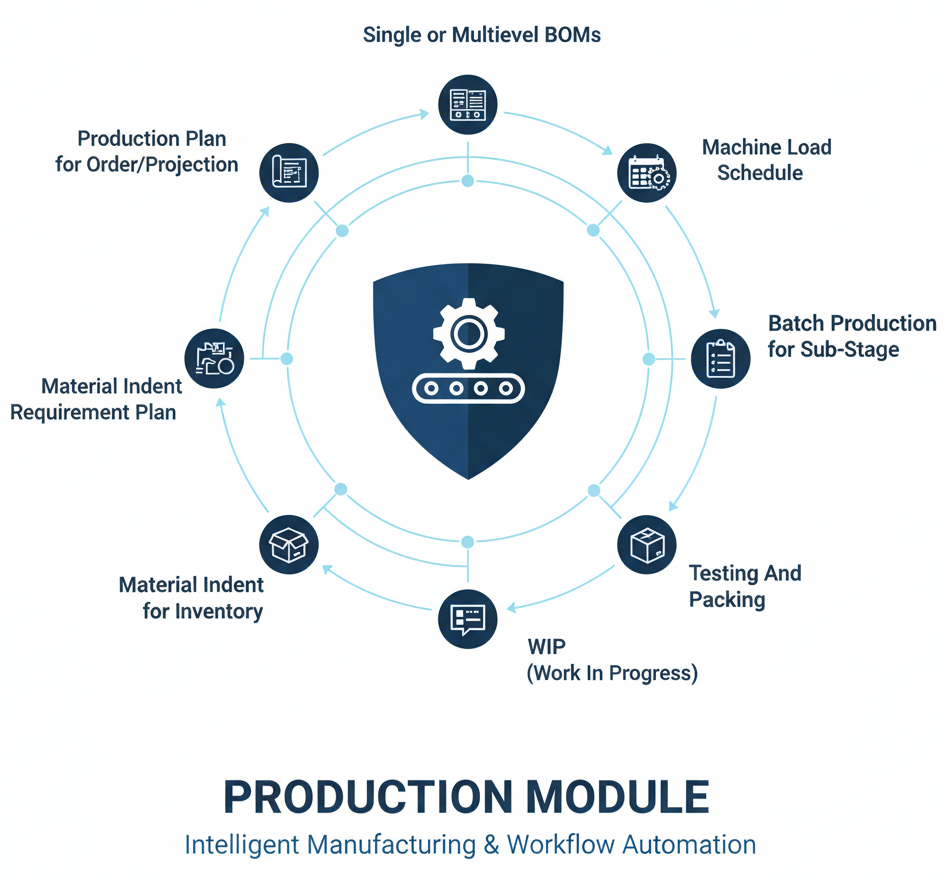

module

Production

Streamline your entire production lifecycle with SwipfeERP. Plan, track, and optimize manufacturing operations with real-time visibility. Manage raw materials, monitor work orders, automate production scheduling, and ensure quality control. Improve efficiency, reduce downtime, and achieve faster delivery with our centralized and easy-to-use production tools.