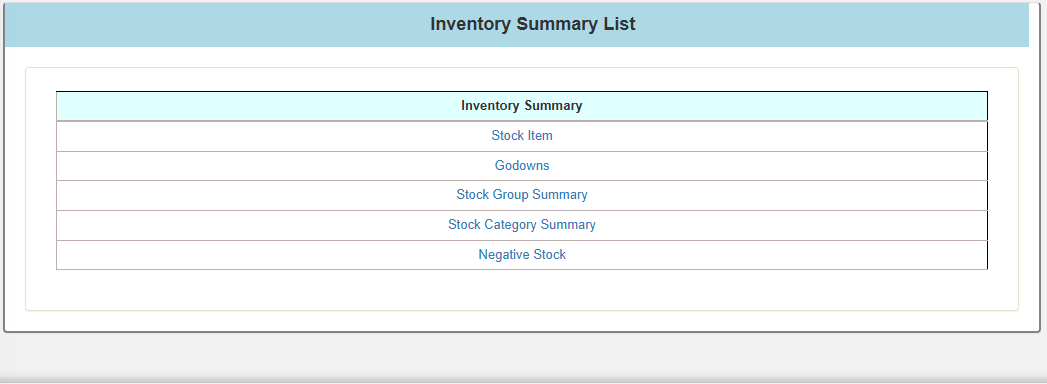

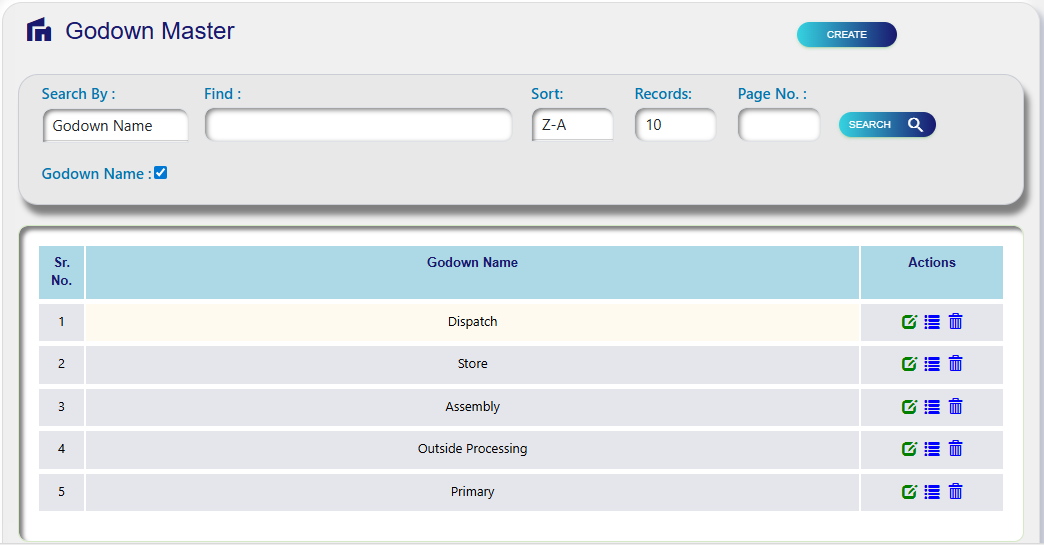

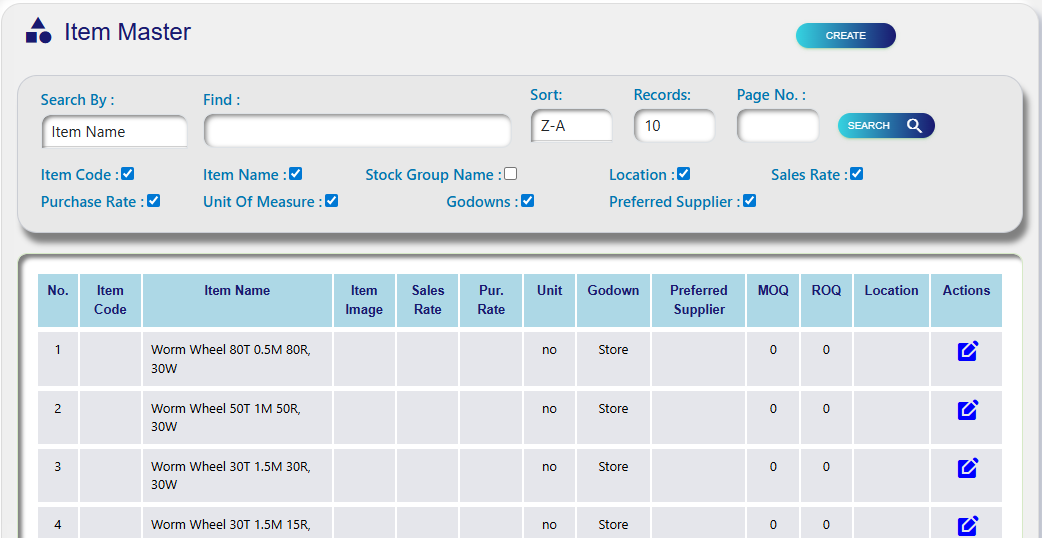

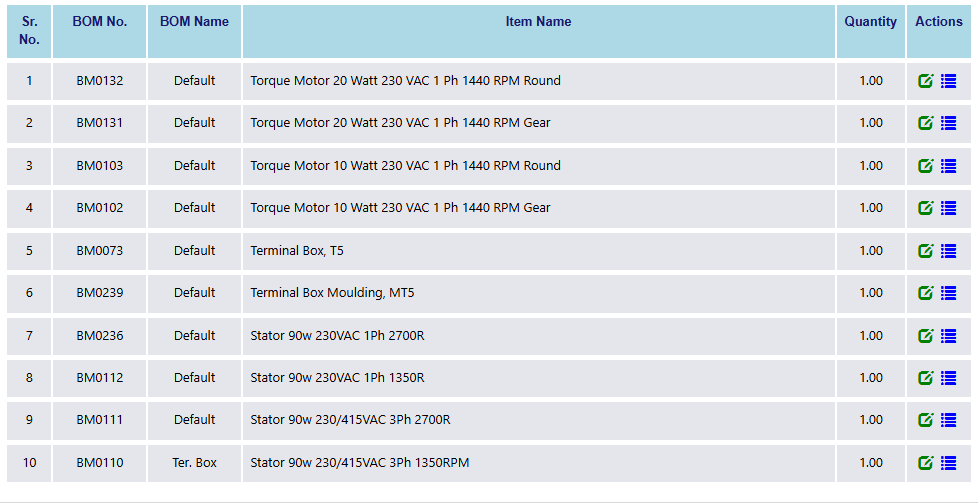

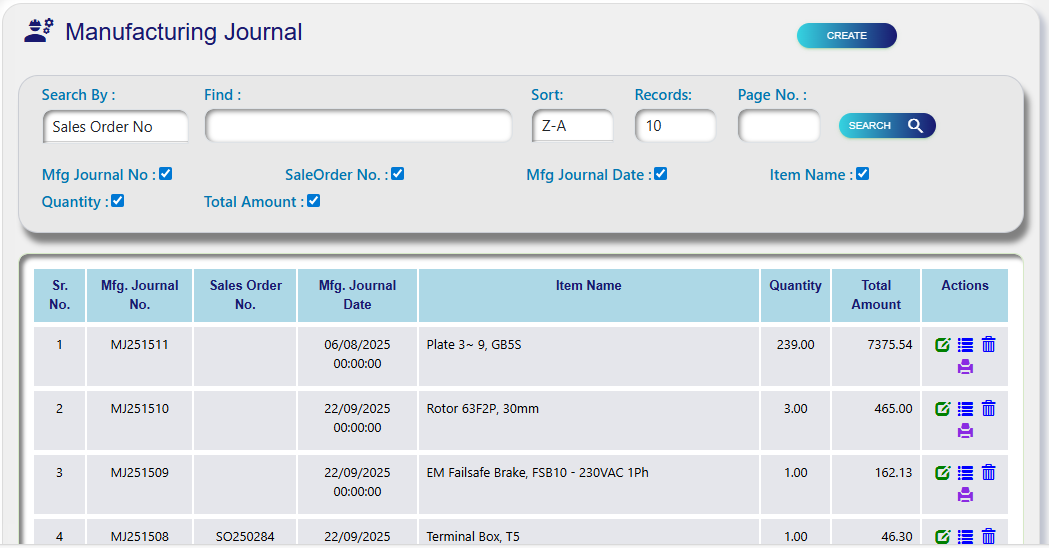

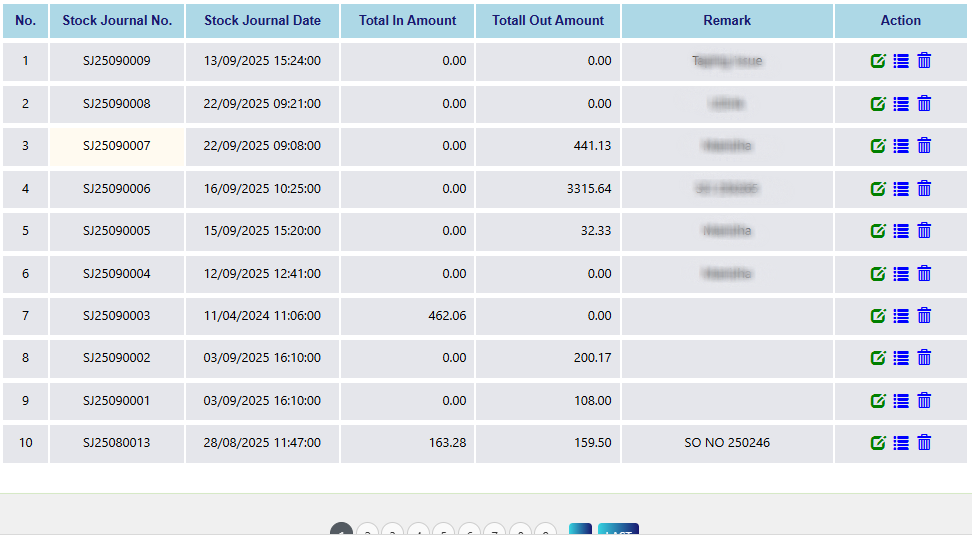

Inventory Summary provides a comprehensive view of all stock items, their quantities, and valuations. You can monitor available, reserved, and allocated stock in real-time. Alerts notify teams about low stock levels or overstock situations. Integration with sales, procurement, and production modules ensures accurate updates. Historical data helps in analyzing stock trends and planning inventory replenishment. Reports provide insights into item movements, stock aging, and valuation. Multi-location tracking allows monitoring stock across godowns or warehouses. The interface is intuitive, enabling quick updates and stock verification. Exporting inventory summaries for audits or management review is easy. It reduces stock discrepancies and improves decision-making. Overall, Inventory Summary enhances visibility, optimizes stock levels, and strengthens operational efficiency.

.png)